As the market for electronic components grows, non-original products have become more common, causing significant losses to business from financial losses to reputational damage.At ANDESOURCE, we understand the threats from non-original parts and have built a meticulous process to exclude non-original products, ensuring only original components reach our clients.

Four Inspections for authenticity verification

ANDESOURCE is a top player when it comes to ensuring the authenticity of electronic components.We combine cutting-edge technology with industry expertise to guarantee the originality of every product, excluding non-original products through the 4 inspections outlined below.

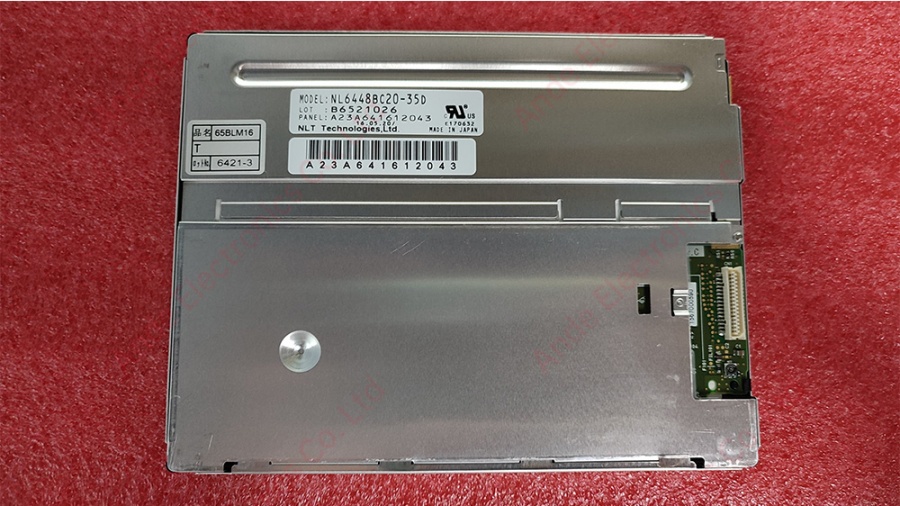

1. Thorough Visual Inspections

The first step in our defense against non-original components is a detailed visual inspection. This process includes high-magnification checks to confirm the physical integrity of components. Our inspectors look for indicators such as tampering, incorrect labels, or signs of prior use. The integrity of labels and markings is confirmed through rigorous solvent tests, ensuring they haven’t been altered. By focusing on the minute details of packaging and component marking, we catch a wide range of non-original attempts.

2. X-Ray Imaging for Hidden Defects

ANDESOURCE goes beyond surface-level checks. Our X-ray testing allows us to examine the internal structure of each component. This high-tech imaging reveals any internal defects, such as internal shorts, open circuits, or inconsistencies in the die and wire bonding—common signs of non-original manufacturing. With X-ray technology, we can detect flaws that other inspection methods miss.

3. Internal Chip Inspection: Looking Inside

To further verify authenticity, we perform internal chip inspection. By carefully removing the outer casing of a component, we can inspect the internal chip for manufacturer markings, copyright dates, wire connections and other critical details. This process ensures that the component inside matches what’s printed on the outside, providing another layer of protection against non-original parts.

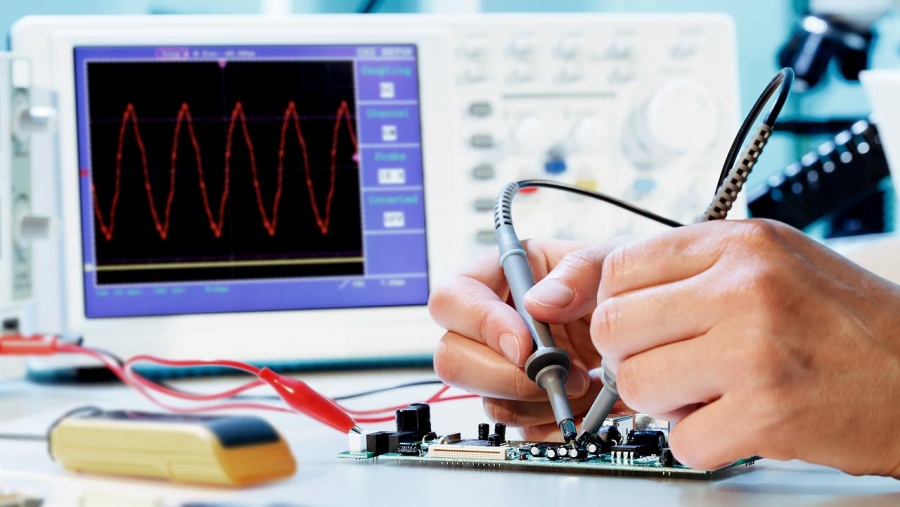

4. Electrical Testing for Performance Assurance

Non-original components often fail to meet performance standards. To combat this, ANDESOURCE conducts electrical testing on each part,simulating real-world conditions to assess each component’s performance. We measure key performance parameters, including voltage, current, and resistance, to confirm that every component meets its expected specifications. This guarantees that only fully functional, authentic parts reach your production line.

Partner with ANDESOURCE for Authenticity and Reliability

ANDESOURCE is committed to delivering only the highest quality, original components, backed by our comprehensive non-original ICscreening process.

Protect your supply chain and your reputation by partnering with ANDESOURCE today. Contact us to learn more about how our distribution services can provide the peace of mind you need, with guaranteed authentic components every time.