In modern electronic products, liquid crystal displays (LCDs) have become an indispensable component. Whether in smartphones, tablets, laptops, or industrial control and medical equipment, LCDs play a crucial role. However, despite the wide variety of LCDs available in LCD industry, customers still face numerous pain points when selecting and using them. This article will thoroughly analyze the pain points of LCD products and explore effective solutions to address these issues.

I. Poor Display Performance

1. Insufficient Brightness and Contrast

Customers have different requirements for the brightness and contrast of LCDs in various application scenarios. For instance, devices used outdoors need displays that maintain good visibility under strong light. However, many customers report that the LCD products they purchase lack adequate brightness and contrast, making it difficult to see clearly in bright conditions.

2. Inaccurate Color Reproduction

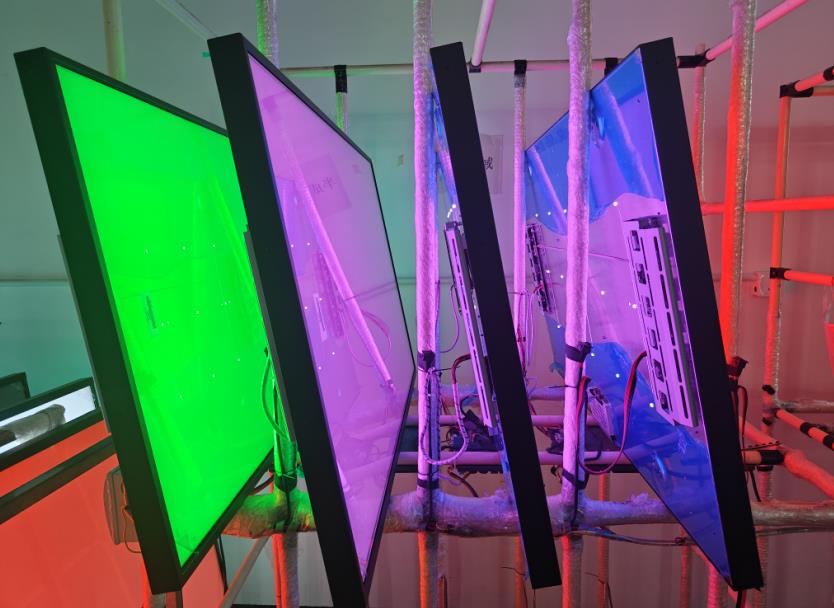

Color reproduction is a critical metric for evaluating display quality. Many customers complain that their LCDs do not accurately reproduce colors, affecting the realism of images and videos. This is particularly crucial for fields requiring high-precision color reproduction, such as medical displays and photography.

II. Short Lifespan

The lifespan of LCDs is another significant concern for customers. Many find that after using LCD products for a period, the screen brightness decreases, dead pixels appear, or the display stops working entirely. This issue is especially critical in industrial settings, where equipment needs to operate reliably for long periods. The lifespan of the LCD products directly impacts the overall performance and reliability of the equipment.

III. Poor Interference Resistance

In specific environments, such as factories and mines, LCDs need to have strong interference resistance. However, many customers report that their LCDs easily experience screen flicker and image distortion in high electromagnetic interference environments, affecting normal use.

IV. High Costs

Despite continuous technological advancements and gradually decreasing production costs, high-performance LCDs remain expensive. This poses a significant financial burden on some small and medium-sized enterprises and individual users. Additionally, the high maintenance and replacement costs also deter customers.

V. Compatibility Issues

The compatibility of LCD products with different devices is a primary concern for customers. Many find that after purchasing an LCD, it is incompatible with their existing systems or devices, leading to unusable displays or requiring additional adaptation, increasing the cost and complexity of use.

VI. Delivery Delays

Many customers report that they have to wait weeks or even months to receive their products after placing an order, severely impacting their production schedules and market responsiveness. Furthermore, unexpected demand or urgent orders exacerbate delivery issues, making it difficult for manufacturers to quickly adjust production plans to meet urgent needs. International logistics uncertainties also affect delivery times, with shipping delays and customs clearance issues making delivery times unpredictable. Poor communication is another significant factor contributing to delivery problems, with customers struggling to get timely updates on order status and progress, lacking transparency in LCD industry.

VII. Inadequate After-Sales Service

As electronic products, LCDs inevitably encounter various issues. During use, customers often need timely technical support and after-sales service from manufacturers in LCD industry. However, many report inadequate after-sales service, with problems not being resolved promptly, affecting the user experience.

Solutions to Address Customer Pain Points

Enhance Display Performance

To meet the high demands for display performance, manufacturers should continuously improve the brightness, contrast, and color reproduction capabilities of LCDs during research and production. For example, using higher brightness backlights, optimizing liquid crystal materials, and filter technology can significantly enhance display performance to meet customer needs in various application scenarios.

Extend Lifespan

Using high-quality materials, optimizing production processes, and strict quality control can effectively extend the lifespan of LCD products. Additionally, manufacturers should provide detailed usage and maintenance guides to help customers use and maintain their displays properly, prolonging their lifespan.

Improve Interference Resistance

For specific environments, manufacturers should develop LCDs with strong interference resistance. Increasing shielding layers, optimizing circuit design, and using anti-interference materials can significantly enhance interference resistance, ensuring stable operation in complex environments.

Reduce Costs

To lower the purchasing and usage costs for customers, manufacturers should continuously optimize production processes, improve production efficiency, and reduce production costs while ensuring product quality in LCD industry. Additionally, offering a variety of product choices to meet different customer budgets can help alleviate financial pressure.

Solve Compatibility Issues

During product design and development, manufacturers should fully consider compatibility issues between displays and various devices and systems. Standardized interface design, detailed compatibility descriptions, and technical support can help customers resolve compatibility issues and enhance the user experience.

Optimize Supply Chain Management

First, optimizing supply chain management. Establishing close cooperation with suppliers to ensure timely supply of raw materials, reducing intermediate links, and improving production efficiency can shorten production cycles. Secondly, increasing the flexibility of production planning. Establishing an efficient logistics system is also crucial. Selecting reliable logistics partners, optimizing transportation routes, and ensuring products are delivered to customers quickly and safely are essential in LCD industry. Additionally, manufacturers should provide transparent order tracking systems, allowing customers to monitor order progress in real-time and reduce uncertainties.

Provide Quality After-Sales Service

To enhance customer satisfaction, manufacturers should establish a comprehensive after-sales service system, providing timely, professional technical support and problem-solving solutions. Establishing online service platforms, offering remote technical support, and regular follow-ups can help customers resolve various issues during use, improving the product experience in LCD industry.

Conclusion

As an essential component of modern electronic products, customers face numerous pain points when selecting and using LCD products. By enhancing display performance, extending lifespan, improving interference resistance, reducing costs, resolving compatibility issues, and providing quality after-sales service, manufacturers can effectively address customer pain points, increasing product competitiveness and customer satisfaction in LCD industry.

ANDE, with over 20 years of experience in LCD products and solutions, always prioritizes customer satisfaction, consistently providing high-quality LCD products and practical solutions, earning the support and favor of many customers worldwide. Their strong after-sales team further ensures a smooth journey for customers seeking electronic products.

Any question or inquiry, pls feel free to contact us: [email protected]

For more LCDs and ICs, pls visit: www.andesource.com